Compressed air filtration

Compressed air filters ensure clean and dry compressed air

Compressed air filters are an essential component in a compressed air system. They ensure that your compressed air is clean and safe to use, and it extends the life of your compressed air equipment. A compressed air filter also known as a line filter ensures that impurities such as moisture, oil and dust are removed from your system.

We supply you with standard high quality compressed air filters from Parker Domnick Hunter, Hiross, Zander or Kaeser.

Contamination of compressed air

A compressed air filter ensures that impurities such as moisture, oil and dust are removed from your system.

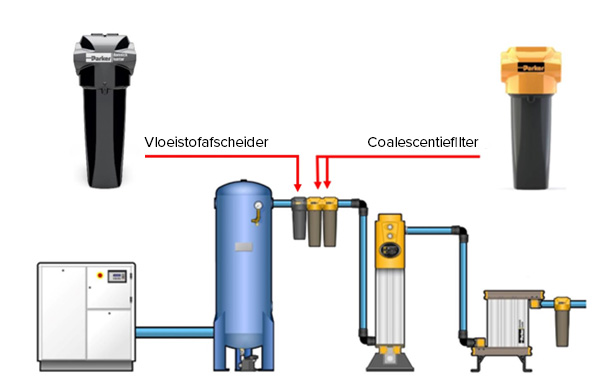

Liquid separators (Cyclone separators)

A liquid separator also called a cyclone separator is actually not a filter but a separator. This element ensures that large amounts of liquid are removed from the compressed air. They thus relieve the dryers from the compressed air system.

Untreated compressed air contains many types of contaminants that must be treated to make a system safe, efficient and cost-effective. Water (and to a lesser extent liquid oil) is present in all compressed air systems. Extracting liquids from compressed air is usually the first filtration process when treating compressed air.

- Fluid separators reduce the amount of water and oil in the pipe;

- They are often placed before coalescence filters;

- They are also found in compressors and refrigeration dryers;

- Liquid separators do not remove water in the aerosol or steam phase.

Coalescence filters

- Aerosols of oil;

- Aerosols of water;

- Solid particles such as atmospheric particles;

- Rust;

- Lime scale;

- Microorganisms.

Oil vapor filters

Oil vapor is present in all compressed air systems, even in oil-free compressors. Untreated residual oil vapor can begin to cool, condense and it then creates liquid and oil aerosols in the compressed air line and/or equipment.Although many systems are protected with oil vapor reduction systems in the compressor room, years of contamination in the distribution lines, from untreated compressed air, can still result in the presence of oil vapor, liquid and aerosol oil at the point of use. An additional filter may be installed at critical points to treat contamination in the distribution lines, these may be too large for some smaller point-of-use applications, for this purpose oil vapor filters are applied at the point-of-use.

OIL-X Domnick Hunter compressed air filtration

The origins of today's compressed air filtration go back to 1963. It was there that Domnick Hunter first began using microfiber filters as a purification application for compressed air.

Domnick Hunter's OIL-X filter was the first of its kind with this groundbreaking technology. Parker Domnick Hunter's OIL-X series has continued to evolve over the years. The filters lead the way in compressed air filtration technology and have a perfect balance of air quality, energy savings and service life.

Kuil Nicos has been appointed by Parker as certified distributor for the Domnick Hunter filtration package. So you have come to the right place when it comes to Domnick Hunter compressed air filtration.

Customized advice?

Want to know the best solution for your situation?

Contact us at

053-435 88 96 or info@kuilnicos.nl.