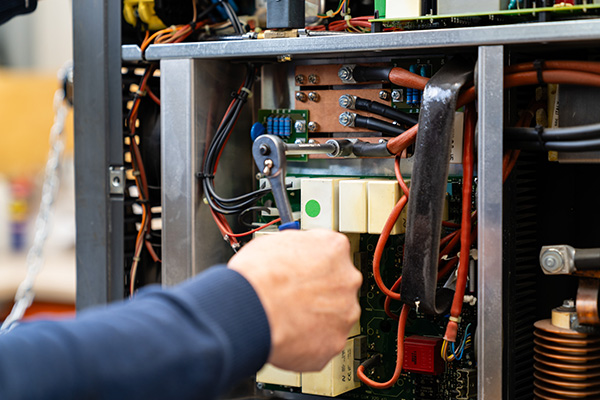

Welding equipment maintenance

Maintenance, repair and validation of welding equipment, according to NEN 3140, NEN 50110-1 and EN 50504 standard, are in trusted and capable hands with us. We maintain and repair your machinery in our modern workshop or at your location. Thanks to years of experience and skilled personnel, we can maintain and repair any type of welding machine and accessories for you.Do you need maintenance? Call 053 - 435 88 96 or mail to info@kuilnicos.nl

Maintenance of your welding machine(s)

Welding equipment maintenance is essential for optimal performance and safety during welding. By performing regular maintenance, failures can be prevented and the equipment continues to operate reliably and efficiently. In addition to the maintenance of welding equipment, we also perform periodic inspections according to NEN 3140 and NEN 50110-1.Need to have your welding equipment repaired (urgently)? We make sure that your equipment will always keep working optimally. In addition, we ensure that your welding equipment keeps running with annual maintenance to prevent downtime.

Validation according to NEN 50504

Besides the standard NEN 3140 inspection, we can also validate your equipment according to the NEN 50504 standard. This is mandatory, for example, if your company must comply with the EN 1090 standard.

Maintenance, repair and validation

Annual maintenance on your welding equipment will save you costs on possible repairs. Regular maintenance also reduces the chance of malfunctions, keeping your production process running optimally. To keep working to the right standard, we also calibrate your equipment.

We maintain, repair and validate:

- MIG/MAG/TIG welding machines;

- Inverters;

- Plasma cutters;

- Spot welding equipment;

- Electrical equipment;

- Orbital equipment;

- Autogenous welding and cutting equipment;

- Reducers;

- Welding torches;

- Welding fume extraction.

Customized advice?

Want to know the best solution for your situation?

Contact us at

053-435 88 96 or info@kuilnicos.nl.